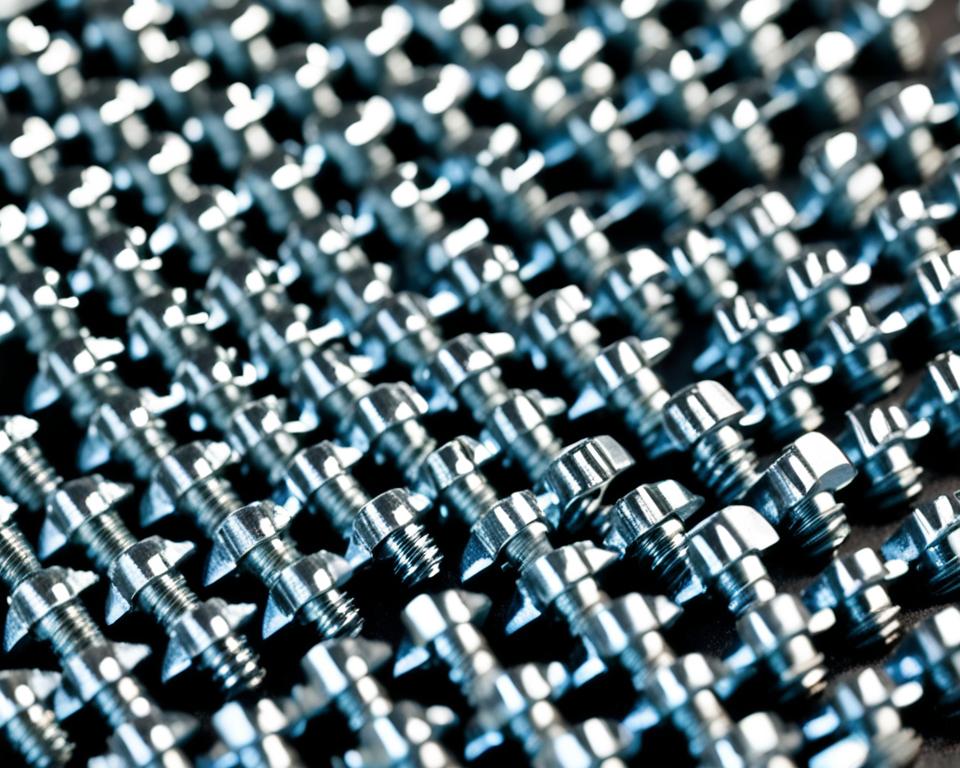

The key to a successful build lies in the small details – the screws. How do we ensure these pieces are driven and secured properly? Knowing the different screw drive types for DIY projects and professional applications helps a lot. The right screwdriver makes your work more accurate and long-lasting.

Consider the Flathead screwdriver. It’s essential in carpentry, woodworking, and electrical applications. Next, we have the Phillips screwdriver, developed in the 19th Century by Henry Phillips. It offers better control for furniture assembly and building. Then, there’s the Robertson screwdriver, loved in Canada for its superb torque control.

Looking globally, the Pozidriv screwdriver stands out in Europe for its stability and reduced slip. Elsewhere, Tri-Wing screwdrivers are used by technicians in electronic repairs. There’s a tool for every task, from secure fastening with pin-in-star screwdrivers to precise work in tight spaces with impact screwdrivers.

Every tool, like the Hex screwdriver for flat-packed furniture, highlights the need for the right screwdriver. Investing in a comprehensive screwdriver set isn’t just buying tools. You’re investing in your projects’ longevity and your ability to tackle various tasks with skill and confidence.

Understanding the Essentials of Screw Drive Types

Choosing the right screwdriver needs a good understanding of screw head types. The selection should match the job’s needs. This ensures work is done well and safely. For example, mechanical environments or precision jobs need specialized screwdrivers.

Different materials are used to make screwdrivers, each for a specific use. Carbon Steel is tough, perfect for everyday jobs. Cr-Mo Steel is better for heavy use because it resists wear well.

When picking a screwdriver, the handle’s design matters too. It’s about what material it’s made from and how it feels in your hand. Metal handles are great for precision. Rubber grips work best where there’s oil or moisture, as they help you hold on tightly.

p>

| Material | Properties | Common Use |

|---|---|---|

| Carbon Steel | Strong, hard | Less demanding tasks |

| Cr-Mo Steel | Wear-resistant, tough | High endurance environments |

| Cr-Vn Steel | Durable, good wear properties | Automotive tools |

| S2 Tool Steel | Abrasion-resistant, hard | Precision machined screw tips |

| Stainless Steel | Corrosion-resistant | Applications requiring hygiene |

The right choice of screw head types is key for screwdrivers in diverse tool applications. Tips made from S2 Tool Steel or coated with Titanium Nitride (TiN) last longer. They withstand abrasion and lower friction, fitting demanding jobs well.

Knowing which screwdriver to use can make or break a project. From furniture assembly with a Phillips head to electronic repairs with a Torx, using the right tool is crucial. The development of screwdriver materials and designs means there’s always the perfect tool for any task, whether you’re a pro or a DIY fan.

The Versatile Flathead Screwdriver and Its Applications

The Flathead screwdriver is simple but effective. It’s great for jobs needing careful work like carpentry. Its wedge-shaped tip fits perfectly into slotted screws. These screws are common in traditional joinery and cabinetry.

Recognizing Flathead Characteristics

The Flathead screwdriver is both durable and flexible. It has a flat blade that slides into slotted screws easily. This lets you apply a lot of force, which is key in carpentry for strong, precise work. Its ongoing use shows how important it is for both old and new carpentry.

Where Flathead Screwdrivers Excel: Usage Scenarios

In woodworking, the Flathead screwdriver is a top choice for its simplicity and usefulness. It works well in various tasks. Whether putting together complex furniture or building sturdy frames.

The Flathead screwdriver is also key in electrical tasks where slotted screws are used. It allows for careful work, perfect for fitting electrical plates and certain woodworking projects.

The Flathead screwdriver is more than just for screws. With its solid tip and handle, it’s great for prying tasks in carpentry. This includes opening paint cans or scraping off excess material. It’s a multitasker in any toolkit.

| Task | Tool Efficiency | Common Applications |

|---|---|---|

| Assembly/Disassembly | High | Furniture, Cabinstry |

| Precision Work | Medium | Electrical Fixtures, Decorative Woodwork |

| General Carpentry | High | Framing, Repairing Wooden Structures |

| Prying | Low | Opening Cans, Removing Nails |

The Flathead screwdriver excels in more than just regular screwing tasks. Its classic design makes it a dependable choice for many carpentry and woodworking jobs. This shows that the simplest tools are often the most crucial for top-grade craftsmanship.

Phillips Screwdrivers: The Crosshead Convenience

Henry Phillips introduced Phillips screwdrivers in the late 1930s. They have been essential in electronics, automotive, and construction since then. Their crosshead design offers great grip and control. This makes them ideal for tasks needing precise torque with little cam-out.

Invention and Evolution of Phillips Screwdrivers

Henry Phillips created the Phillips screw in response to the automotive industry’s demands in the 1930s. Patented in 1936, its self-centering feature minimized slippage and damage. This innovation boosted productivity and reliability in fastening tasks.

Control and Precision: Phillips in Everyday Use

Phillips screwdrivers excel in high-torque applications and slip less than other types. They come in various sizes, suited for many jobs. Whether it’s assembling furniture or installing electronic devices, Phillips screwdrivers with their crosshead tips do the job well.

Phillips screwdrivers are popular for their precise screw engagement. Here are important features that show why professionals prefer them:

| Feature | Phillips | Pozidriv |

|---|---|---|

| Radial Points | 4 | 8 |

| Year Introduced | 1936 | 1962 |

| Common Uses | Electronics, Automotive, Construction | Higher torque applications in Europe |

| Reduced Cam-out | Good | Better |

Phillips screwdrivers are beloved for their efficiency and ease of use. They meet the fastening needs of both household and professional projects. The legacy of Henry Phillips continues to influence the tool industry greatly.

The Importance of Torx Screwdrivers in Mechanical Applications

Torx screwdrivers are crucial in mechanical fields. Their 6-pointed star tip sets them apart. These tools are vital in industries needing high precision and strength. They are perfect for the automotive, construction, and electronics areas because they can transfer a lot of torque without slipping.

One key benefit of Torx screwdrivers is their ability to prevent camming out. This feature saves the screwdriver and screw from damage. It also increases tool life. Such durability is essential for pros needing dependable tools for critical jobs.

Standardized by the International Organization for Standardization as ISO 10664, Torx screws and screwdrivers represent a key innovation in fastening technology, developed originally by Camcar Textron in 1967.

- Torx screwdrivers give a consistent torque output, important for precise tasks.

- They fit perfectly with Torx screws, which range from T1 to T100 in size.

- New Torx Plus and Torx ttap systems offer better torque and less wobble.

Torx screwdrivers keep improving for secure, high-torque tasks. They are essential in sectors from electronics assembly to vehicle construction. Their preference shows the critical role they play in modern tool kits.

For tasks like fixing a motorcycle or installing a hard disk, Torx screwdrivers are ideal. Their precision, durability, and resistance to damage make them top choices for experts aiming for perfection.

Robertson Screwdrivers: Canada’s Square Drive Masterpiece

Robertson screwdrivers shine with their sturdy design. They introduced a square drive for better torque control. This breakthrough has improved work in fields like the automotive and furniture industries. The design reduces slippage, making the tools more efficient and reliable for users.

Unique Torque Control of Robertson Screwdrivers

The square drive of Robertson screwdrivers fits snugly. This increases grip and lowers the chance of wear on both the screw head and driver bit. It’s why these screwdrivers last longer and are safer for heavy use. Professionals and hobbyists alike prefer them for their durability and safety.

Diverse Industry Applications of Square Drive Screwdrivers

Square drive screwdrivers excel in various fields. They are perfect for building sturdy decks or putting together electronics. Robertson screwdrivers are known for their precision. This makes them ideal for jobs requiring stability and torque control, from automotive work to furniture crafting.

These screwdrivers are becoming more popular in different industries. They blend traditional screwdriving with new features that meet today’s fastening needs. The growing use of Robertson screwdrivers shows a trend towards tools that are both easy to use and high-performing.

Hex Screwdrivers and Their Role in Furniture Assembly

Choosing the right tools is key when putting together furniture. Hex screwdrivers and Allen key screwdrivers are must-haves in your kit, especially for items that come flat-packed. These tools are made for hexagonal-shaped recesses. They fit perfectly, ensuring the right amount of force is used to tighten pieces without damage.

Hex screwdrivers look a lot like Allen key screwdrivers. They work with hex head screws, which you see a lot in homes and factories. These screwdrivers are important for screws that have a hexagonal shape inside. They’re sturdy, which means they can tighten screws well without ruining them or the furniture.

Choosing the right screws and screwdrivers is crucial when making furniture last. Hex and Allen screws are top choices because they work well and keep things secure. Let’s look at how different screws are used:

| Screw Type | Common Use | Tool Required |

|---|---|---|

| Hex Head Screws | Furniture, Industrial Equipment | Hex Screwdriver |

| Button Head Screws | Low-profile Furniture Pieces | Allen Key Screwdriver |

| Cap Head Screws | Modern, Sleek Furniture Designs | Hex Screwdriver |

Knowing why hex screwdrivers are great for furniture assembly matters. They’re perfect whether you’re setting up a simple shelf or a complex cabinet. The right hex screwdriver makes assembling furniture smoother, ensuring everything fits snugly and holds tight.

Hex screws not only make assembly easier but also help your furniture last longer and look better. This shows how important it is to pick the right tool, like a hex or Allen key screwdriver. Choosing correctly makes assembly easier and ensures your furniture looks great for years.

An In-Depth Look at Pozidriv Screwdrivers’ Benefits

Tools these days need to handle tough construction and assembly work. Pozidriv screwdrivers stand out because they offer enhanced stability and reduced cam-out. They’re perfect for tasks where precision and strength are key, especially when applying high torque is common.

Comparing Pozidriv to Other Screw Drives

Standard Phillips screwdrivers often slip under high torque. But Pozidriv screwdrivers fit snugly because of their unique design. Their design includes extra ribs at 45 degrees to the main cross. This gives more contact points and reduces slippage. Reduced cam-out not only protects the screw heads but also ensures the user’s safety by preventing slips.

Each type of screwdriver, like Torx or Hex, has its place. Torx screwdrivers work great for automotive projects because of their six-point star tip. Hex screwdrivers are preferred for putting together furniture because of their simple, effective design.

Evaluating the Stabilizing Design of Pozidriv Screwdrivers

Pozidriv screwdrivers are designed for enhanced stability. They fit better into screw heads than Phillips screwdrivers, thanks to their less tapered tip. This stops the driver from popping out when turning hard. This is a big plus for major construction work where accuracy and reliability matter a lot.

The design spreads out the force along the screw head’s sides, not just the tip. This makes the screw and the tool last longer. The ISO’s color-coding standards make it easy to pick the right tool quickly, even when you’re busy.

Pozidriv screwdrivers can take on tough projects without failing. They promise performance and comfort for the user. They are great for heavy industrial use or even for DIY tasks at home. It means less wear on the tool and less effort from the user.

Tri-Wing Screwdrivers and Their Specialized Uses

Tri-wing screwdrivers are crucial in the aerospace industry and for fixing electronic devices. They have a unique pinwheel tip for triangular recess screws. These screwdrivers are made for precision. They make sure sensitive parts are always safe.

The aerospace field first used tri-wing screwdrivers. Now, they are key in electronics, helping top brands keep their products safe and tamper-proof. They are perfect for fixing smartphones or working on airplanes. Tri-wing screwdrivers provide security that regular ones can’t.

This table shows how tri-wing screwdrivers are used in electronic devices and other fields. It highlights the tool’s versatility and special features:

| Industry | Common Usage | Screw Size |

|---|---|---|

| Aerospace | Instrument assembly, interior panel installation | 0.1 mm – 3 mm |

| Electronics | Smartphone repair, camera assembly | 0.1 mm – 1.5 mm |

| Consumer Products | Children’s toys, electronic appliances | 0.5 mm – 2 mm |

The tri-wing screwdriver is vital not just in the aerospace sector but also in electronic assembly. It provides great security and accuracy. Its unique design makes sure electronic items are put together well, which improves their durability and safety.

p>

Tri-wing screwdrivers are key in keeping high safety and quality in making things. Their special design and size choices show the need for precision. From electronics to aerospace, their use is crucial. It shows their focused role in fields needing detail, security, and exactness.

Examining JIS Screwdrivers for Enhanced Engagement

The Japanese Industrial Standard (JIS) screwdrivers are made for incredible precision. They self-center perfectly with cross-point screws. Their design is perfect for jobs that need careful alignment and secure fastening.

Why Choose JIS Screwdrivers for Cross-Point Screws?

JIS screwdrivers solve the cam-out problem that Phillips screwdrivers have. Their tip slots into the cross-point screws snugly. This ensures force is applied accurately. Thus, both the screw and tool stay in good condition, making JIS the better choice for precise work.

Applications that Benefit from JIS Screwdriver Use

Industries like electronics or machinery installations find JIS screwdrivers very useful. Their self-centering quality guarantees precise screw placement. This prevents damage to important parts, improving assembly quality.

JIS screwdrivers shine in high-torque tasks. They keep a solid grip on the screw. This lowers the chance of ruining the screw head. It also adds safety to high-precision jobs.

“`

| Screwdriver Type | Self-Centering | Standard Size Fit | Preferred Use |

|---|---|---|---|

| JIS Screwdrivers | Excellent | Specific to JIS standard | Electronics, High-precision machinery |

| Phillips Screwdrivers | Good | #0 to #5, M1.6 to M6 | General household, Furniture assembly |

| Pozidriv Screwdrivers | Very Good | PZ1 to PZ3 | European appliances, Car manufacturing |

| Slotted Screwdrivers | Poor | 0-1 to 18-24 blade sizes | Simple carpentry, Electrical work |

“`

JIS screwdrivers clearly excel in high-precision and reliability needs. They’re essential for professionals in electronics and precision engineering fields.

Security Screwdrivers: Ensuring Safety with Pin Torx

Security screwdrivers are key for safety in many areas. They’re also known as Security Torx or Pin Torx. These tools have a special pin at the tip that fits into security screws.

This special design is crucial for preventing tampering, especially in sensitive spots.

Security screwdrivers are used everywhere, from schools to high-tech fields. They make sure devices are safe from tampering. By using these tools, places like hospitals and cars stay secure.

They are perfect for everything: simple security to complex military needs. Click here to learn more. Their tough build makes them indispensable in many fields.

| Industry | Type of Screw | Common Use |

|---|---|---|

| Aerospace | Pin Torx | Prevent unauthorized equipment disassembly |

| Automotive | Clutch Head | Secure components exposed to public |

| Hospitals | Oval Pan Screw | Protect medical machines |

| Schools | Snake Eye | Secure technology labs |

The material of Security screwdrivers and screws is very important. They choose strong, lasting materials to prevent corrosion. This choice is critical for keeping devices securely fastened without fail.

Knowing how these screwdrivers work helps pick the best one for any job. This ensures that important systems and devices are protected from unauthorized use or harm.

Impact Screwdrivers: A Heavy-Duty Tool for Tough Tasks

Impact screwdrivers and drivers are perfect for working with dense materials or handling heavy-duty tasks. These tools deliver more torque than traditional drills. This makes them great for tough materials or long-term use.

Impact drivers are not standard drills. They are tougher and have special features for heavy-duty applications. The 1/4’’ hex chuck is a key feature. It fits hexagonal bits and is great for various screw sizes. The MAKITA DTD152Z and MAKITA DTL061Z show the wide price range, from £55 to £207, for these useful tools.

Voltage is key to an impact driver’s performance. Options usually range from 12v to 18v. 18v models are powerful, perfect for intense tasks. The 12v models are lighter and easier to handle, good for long-term use without getting tired.

Knowing the differences between tools helps in making a good choice. Unlike drill drivers, impact drivers are all about high-torque for screwing tasks. They’re great at fastening into dense materials safely and quickly. They also reduce the risk of damaging softer materials or stripping bolts.

Impact screwdrivers come with variable speed triggers. This allows for precise control over speed and torque. They perform well even at low speeds. Improved battery tech makes these cordless models more powerful and portable.

For tool safety and longevity, follow best practices. Always consult the manual and wear the right safety gear. Use the correct accessories. Remove the battery when not in use to avoid accidents. This also helps the battery last longer.

In conclusion, the right impact driver can greatly improve your work. If you’re a professional or need a powerful tool for projects, choosing well is key. Find more tips on selecting tools in this impact driver buying guide.

Conclusion

Choosing the right screwdriver is crucial. It affects both material integrity and safety. Whether you’re working with hardwood or delicate electronics, the right tool is key. This article covers many types, like the Flathead and Tri-wing. Each one has a special role, showing the importance of picking the right one for the job.

For safe screw fastening, high-quality tools like VDE certified screwdrivers are essential. They keep electricians safe from electrical harm. Security screwdrivers add protection by preventing tampering. In Canada, the Robertson is key for cars, while the Phillips is great for DIY projects worldwide.

Knowing which screwdriver to use boosts efficiency and helps your tools and projects last longer. With the right set of tools, you can tackle any job. Learning about these tools is worth it for the quality of your work.

Source Links

- https://www.redboxtools.com/news/screwdriver-types-uses/

- https://home.howstuffworks.com/different-types-machine-screws.htm

- https://www.fastenersystems.com/blog/types-of-wood-screw-heads

- https://www.metmo.co.uk/blogs/news/toolkit-essentials-how-to-choose-the-right-screwdriver

- https://www.bobvila.com/articles/types-of-screwdrivers/

- https://www.midlandtool.com/blog/1043/screwdrivers-the-different-types-and-their-uses

- https://www.huyett.com/blog/screw-head-and-drive-types

- https://www.essentracomponents.com/en-us/news/solutions/fastening-components/what-is-the-difference-between-phillips-and-pozi-screw-heads

- https://en.wikipedia.org/wiki/List_of_screw_drives

- https://allpointsfasteners.com/blog/different-screw-head-types-what-they-are-designed-for.html

- https://en.wikipedia.org/wiki/Torx

- https://www.insight-security.com/what-is-a-torx-screw

- https://www.diversitech-global.com/post/screwdrivers-parts-materials-types-application

- https://www.amazon.ca/Railer-20pc-Screwdriver-Bit-Set/dp/B09ZGBY1GS

- https://paulsellers.com/2022/03/on-fastenings-and-fixings/

- https://www.grainger.com/know-how/equipment/kh-screwdriver-types-uses

- https://www.pbswisstools.com/en/news/detail/phillips-and-pozidriv-cross-head-screws-explained-in-simple-terms

- https://www.homeserve.com/en-us/blog/home-improvement/types-of-screwdrivers/

- https://www.thespruce.com/types-of-screwdriver-5324555

- https://zago.com/resources/what-are-security-screws/

- https://www.howetools.co.uk/news/post/impact-driver-buying-guide